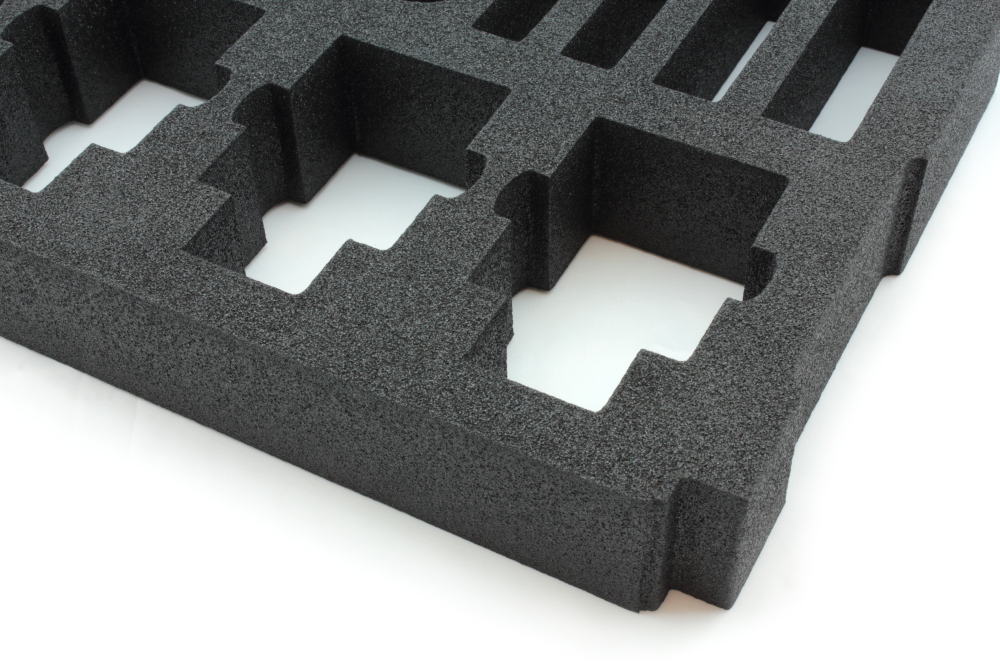

This fantastic material is a closed cell, cross-linked, low density polyethylene foam. Perfect for case inserts, tool organizers and high quality packaging. Polyethylene foam is also commonly used in prop making, cosplay and larp, but also in more industrial settings as gaskets, sound dampening and cushioning.

This foam is both acid free and inert which makes it ideal for archive, presentation and preservation boxes.

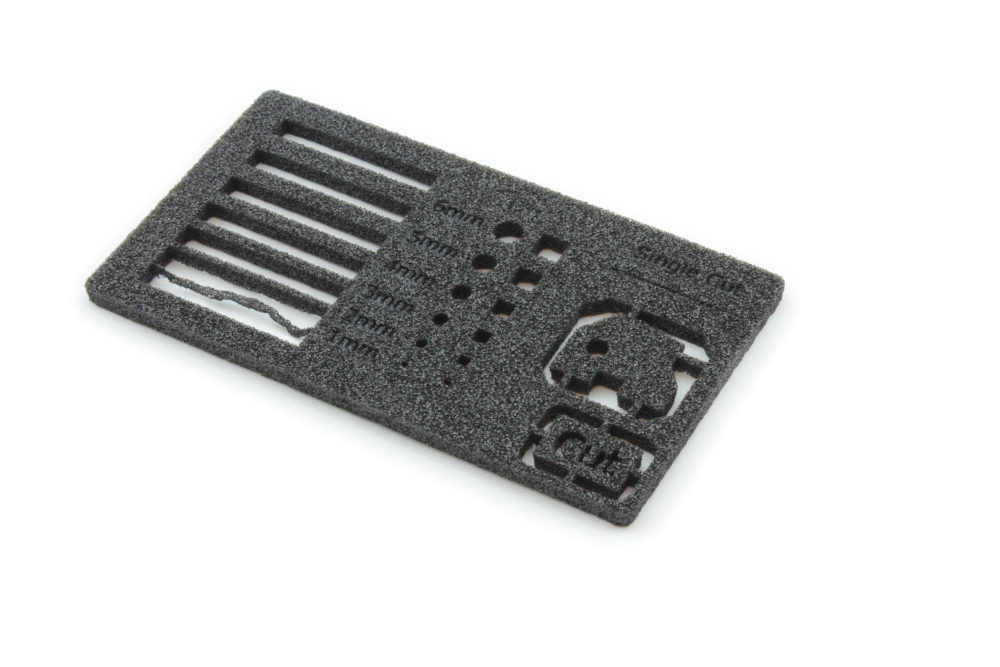

Cuts cleanly and works well with area engraved text.

Take care to not make features that are too thin. The cut width in this material is wide and suffers from a slight curf, especially in the thicker variants. This usually doesn't affect the end product but is good when designing your part.

Since the foam is flexible we suggest that you make your contours a bit smaller than the part its going to hold for that perfect snug fit.

We currently offer LD29 which is of medium density. Suitable for all the applications mentioned above.

LD29 = 29 kg/m3

Available thicknesses and colors

- 50mm - LD29 - Black

- 40mm - LD29 - Black

- 30mm - LD29 - Black

- 20mm - LD29 - Black

- 10mm - LD29 - Black

- 7mm - LD29 - Black - Adhesive Backing

- 5mm - LD29 - Black

- 3mm - LD29 - Black

- 2mm - LD29 - Black

- 10mm - LD33 - Blue

- 5mm - LD33 - Blue

- 10mm - LD33 - Red

- 5mm - LD33 - Red

- 10mm - LD33 - Green

- 5mm - LD33 - Green

- 10mm - LD33 - Yellow

- 5mm - LD33 - Yellow

Cut width

- 20-50mm = ~1.2mm (Width at top surface: ~1.4mm / Width at bottom surface: ~1.0mm)

- 10mm = ~0.7mm

- 5mm = ~0.6mm

Cut Curf

20-50mm = ~0.4mm

This is the difference in cut width from the top surface to the bottom surface.

Sheet Size

980mm * 650mm

How does it look once laser cut?

Benefits:

+ Absorbs energy

+ Cuts cleanly

+ Can be glued using contact cement

Drawbacks:

- Line engraving is hard to see

- Thin features will melt away during the cutting process

Mechanical properties:

- Density: 29 kg/m3