Because of it is low-density and high strength, balsa is a very popular material for light, stiff structures in everything from model aircrafts to core material in windtubine blades.

We offer balsawood in three different weight classes:

- Weight class light: max 90 kg/m³

- Weight class medium: 126 – 155 kg/m³

- Weight class dense: min 156 kg/m³

Available thicknesses and colors

- 6mm - Light - Natural

- 5mm - Light - Natural

- 4mm - Light - Natural

- 3mm - Light - Natural

- 2mm - Light - Natural

- 1mm - Light - Natural

- 6mm - Medium - Natural

- 5mm - Medium - Natural

- 4mm - Medium - Natural

- 3mm - Medium - Natural

- 2mm - Medium - Natural

- 1mm - Medium - Natural

- 6mm - Dense - Natural

- 5mm - Dense - Natural

- 4mm - Dense - Natural

- 3mm - Dense - Natural

- 2mm - Dense - Natural

- 1mm - Dense - Natural

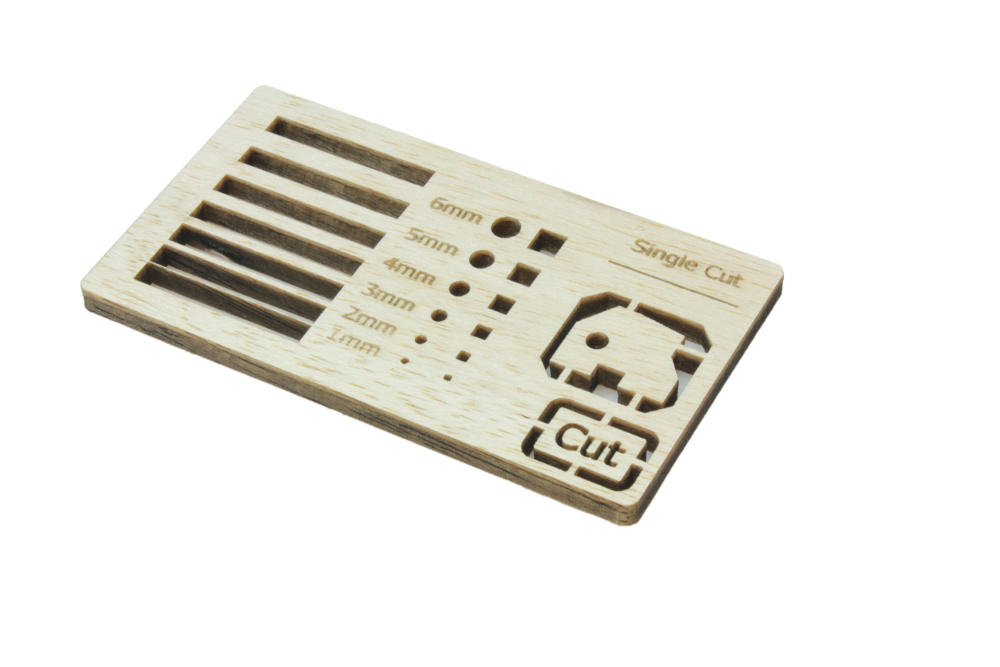

Cut width

~ 0.08-0.2mm

In balsa you usually don't need to compensate for the cut width. Just draw your parts with zero play and then let the laser beams width remove just a tiny bit more material to make your parts easier to assemble.

Sheet Size

994mm * 94mm

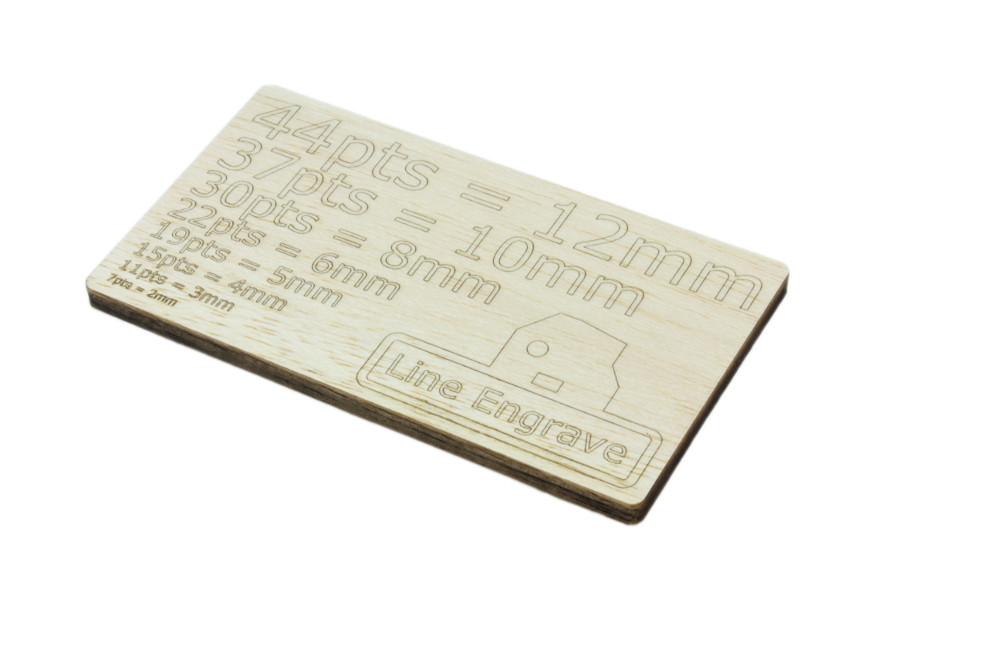

How does it look once laser cut?

Hints from TechStation!

When bonding pieces together you can create incredibly strong joints by using a "tab" construction, where the parts are mechanically locked together. This also has the benefit of making the parts easy to align and assemble. Add glue and you are all set!

Instead of using "regular" wood working glue, we recommend that you use Alipatic Resin. This is due to two factors, it dries much faster and creates stronger bonds.

Benefits:

+ Light

+ Good mechanical properties

+ Simple to glue

+ Simple to cut, sand and saw.

Drawbacks:

Mechanical properties:

- Density: 40-250 kg/m3